Decorating and branding your cosmetic bottles can make your brand stand out from the crowd. With a good printing service, you can differentiate your product, make the unique value proposition of each item clear, and comply with federal or international labeling regulations. Pad printing is a high-quality, versatile printing method that can transfer ink-based text and designs right onto the bottle. Learn more about the pad printing process, the benefits it offers, and some of the most advantageous use cases in the industry.

Steps to Pad Printing on Cosmetic Bottles

Cosmetic bottle printing is a five-step process. Your pad printing provider can manage this entire process at low or high volumes to fulfill demand.

- Choosing the Ink: First, match your printing ink with the bottle’s material. Certain inks will work best with glass, plastic, and metal surfaces. You might also select a specialized ink that offers additional benefits.

- Preparing Artwork: Next, your manufacturer can adjust the size, orientation, placement, and complexity of the digital design to facilitate an accurate, high-quality printing process.

- Preparing the Plate: Once the artwork or text layout is finalized, your provider can create the plate, which involves these two steps:

- Etching: The design is etched onto a plate by using etching chemicals or a laser.

- Inking: To start printing, a doctor blade applies a coating of ink onto the plate. Any excess ink is wiped away to create a clean print.

- Ink Transfer: To create the ink print, a pad is pressed over the etched, inked plate, transferring the ink to the pad. Then the pad is pressed against the bottle to deposit the ink onto that surface.

- Curing the Print: Most pad prints must be UV light cured to dry and adhere permanently to the bottle surface.

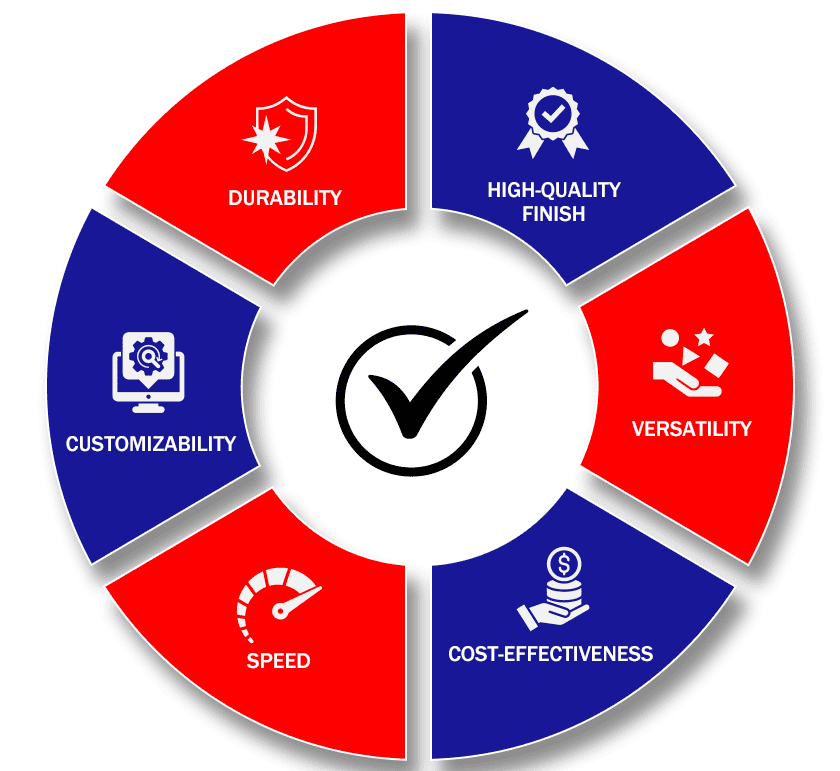

Advantages of Pad Printing on Cosmetic Bottles

Pad printing offers several advantages over other industrial printing processes for cosmetic bottles.

Printing On Cosmetic Bottles

Using Pad Printing

High-Quality Finish

Pad printing creates extremely precise images that capture every detail of the etched design. The final image is colorful, long-lasting, and clear. The results are also highly reproducible, so every bottle looks virtually identical.

Versatility

Cosmetic bottle printing works with a wide range of sizes, shapes, and materials. Pad printing can be used on smooth or curved surfaces, textured planes, and plastic, glass, or metal bottles.

Cost-Effectiveness

Pad printing does not require expensive equipment or specialized labor. It is a cost-effective solution for both low and high volumes of orders, which makes it accessible for both small businesses and large industrial enterprises.

Speed

Pad printing setups can quickly cycle through different bottles to print large volumes on short timelines.

Customizability

Pad-printed designs start with a software file. Designers can change the colors, adjust the size, and add custom graphics to the design, which is then reproduced on an etched pad. Each design or physical pad can be customized to suit the size and other parameters of the product bottle.

Durability

Pad-printed graphics are long-lasting. Once the ink cures, it permanently adheres to the bottle surface and can withstand sunlight, wear, and physical abrasion from scratches, drops, and other scuffs. This results in a package that looks great on the shelf and the entire time the consumer uses it.

Applications of Pad Printing on Cosmetic Bottles

Companies can use pad printing to display virtually any information on their bottles, whether it’s promotional information about your brand or specific product use instructions. Cosmetic bottles need to hold a lot of information, and that includes the following:

- Branding: Companies can add full-color logos and branding to their bottles to establish their brand identity and make their bottles stand out.

- Labeling: Pad printed labeling provides lots of information and can be added to glass or plastic bottles of any size. These labels resist fading, wear, and smudging, providing long-term value to the consumer.

- Customization: Pad printing is entirely customizable. It can work with virtually any design and color palette. It can also transfer the designs onto a wide range of surface types.

- Compliance: Pad printing techniques can ensure bottles display required information like expiration and manufacturing dates, ingredients, and more.

Pad Printing on Cosmetic Bottles From Teca-Print

Since 1989, Teca-Print has provided premium pad printing machines and consumables to a global customer base. We provide custom pad printing services for cosmetic bottles so that your brand can stand out. Contact us today to learn more about our capabilities.