Custom UV/LED Digital Printing Services from Teca-Print USA

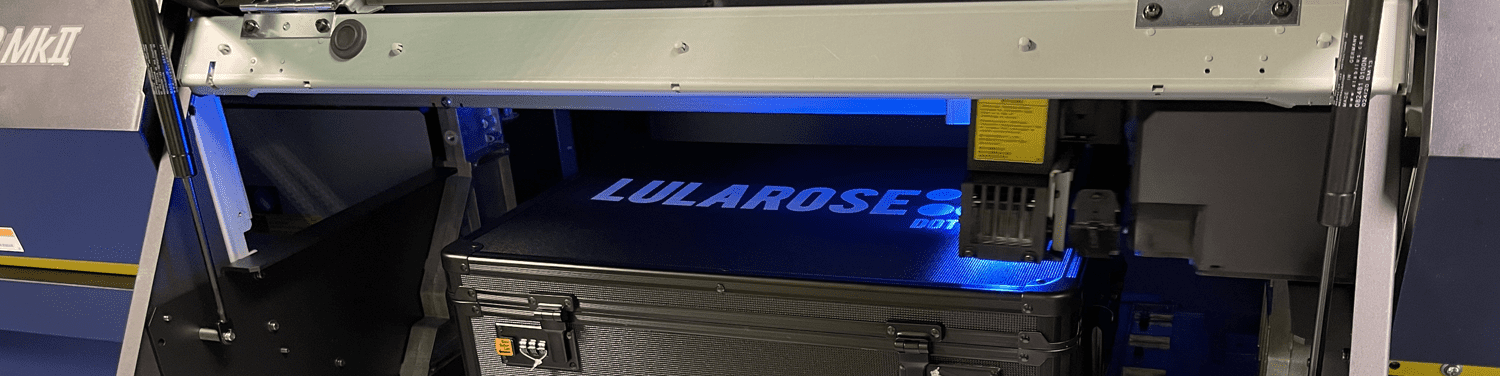

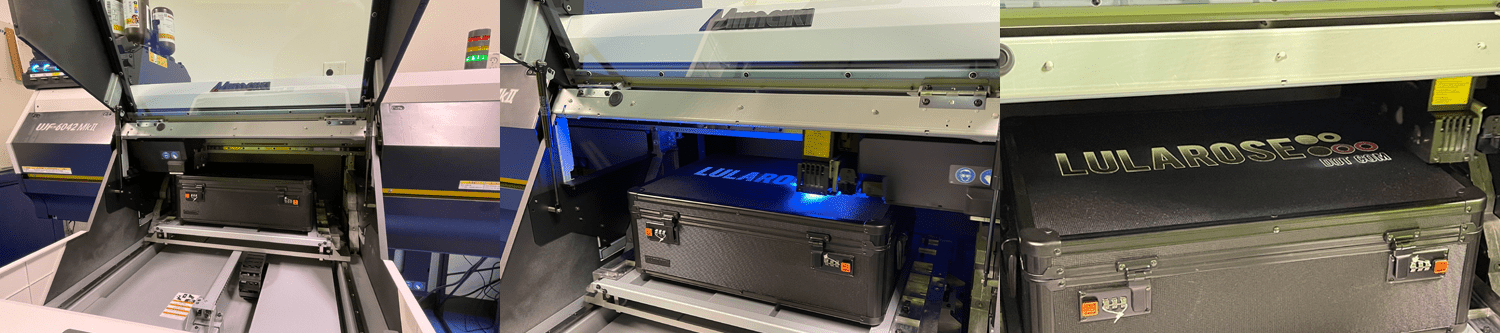

The world of UV-LED printing is relatively new to small to mid-size businesses. Unlike sublimation and heat transfer printing, UV-LED printing is a single-step process where the ink is directly applied to an object and instantly cured by UV light. UV-LED Printing isn’t as labor intensive as sublimation or heat transfer printing, and items come off of the printer ready to deliver to the customer.

UV-LED printers offer production costs that are significantly lower than sublimation and heat transfer printing. This means customer margins on finished goods are higher due to less labor and less ink. UV-LED printing is also the most versatile of the three technologies. With the right UV-LED printer, customers can print on flat and cylindrical surfaces or garment with one machine. Lastly, because the inks are instantly cured and can be layered during the printing process, it’s very easy to print items with texture and dimension, including ADA-compliant signage with Braille.

Advantages of UV direct printing

- Apparent dot sharpness and color saturation are improved because there is little opportunity for ink dots to spread. No ink absorption into the actual substrate. Rather, the inks reside mostly hardened onto the outer surface of the substrate.

- Chemical interaction with the substrate is reduced because of the quick, hard drying, and low absorption properties. This fact opens up doors to a variety of different substrates to be used. More choices means greater opportunity for creative sign solutions such as papyrus paper. Also, there are more opportunities for using diverse recycled materials.

- The special UV inks employed release zero VOC’s,making it a greener process for our environment and a safer one.

- The scratch-resistant surface makes the handling, transportation, and installation much improved. Plus this has a better tolerance to walk-by traffic than most. A tougher product ultimate leads to savings.

- Faster production times because of the instant curing process. Jobs can even be two-sided, and its still a time saver for your UV print provider. Set-up time remains the same regardless of the printing process.

- Lower cost because there is no need for additional materials and labor for mounting onto a second substrate. The surface does not need to be protected by an over-laminate nor to be placed under glass.

- UV prints can be produced with high levels of gloss or dull finishes, depending on the look required for your project.

Our Capabilities:

UV/LED digital printing onto flat or lightly curved objects.

Parts up to 24”x 16” in length and width and up to 5 inches in height.

Full color printing available with white background, primer preprint, and glossy clear overcoat