In pharmaceutical manufacturing, high-quality printing methods are essential for accurately marking products and preventing product misuse or counterfeit attempts. These markings must be clear, consistent, and precise since they often contain critical dosage instructions and manufacturer details. Pad printing allows delicate or uneven substrates to be printed without interfering with product integrity, making it ideal for meeting the high safety and quality standards of the pharmaceutical industry.

At Teca-Print, we create industry-leading custom pad printing solutions that meet the complex needs of the pharmaceutical industry. We act as both the printing service provider and the equipment supplier, reducing lead times for our clients and delivering exceptional quality products.

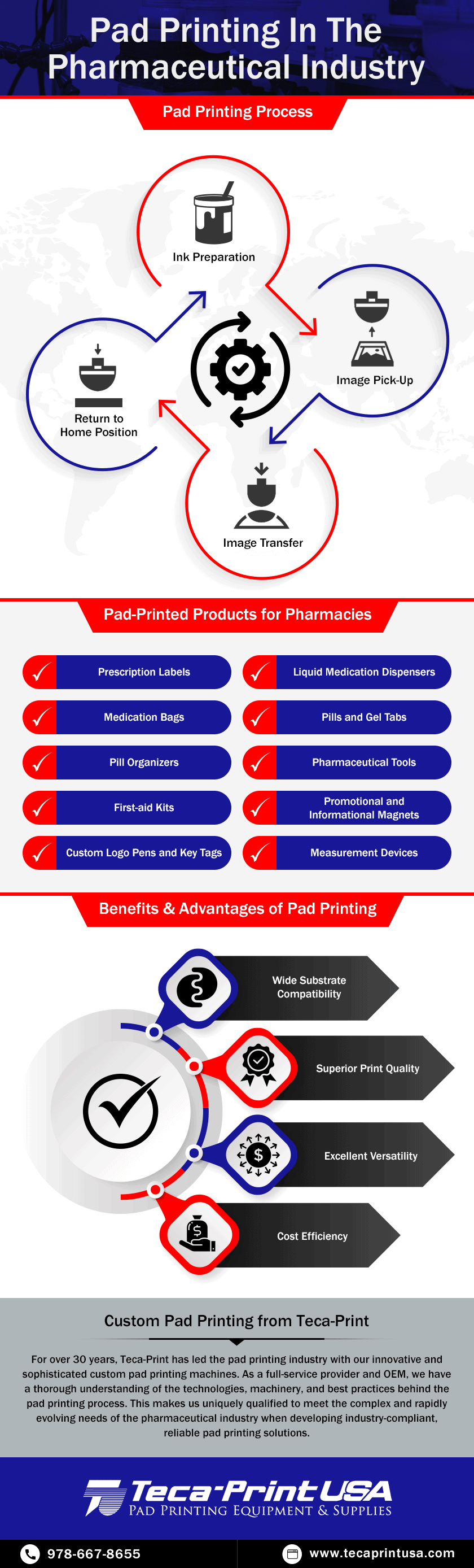

Pad Printing Process

Pad printing is an indirect gravure printing technique that uses a silicone pad to transfer two-dimensional images or prints to three-dimensional surfaces. This method outperforms traditional printing methods when it comes to adding intricate, high-resolution details to irregularly shaped substrates. Basic steps of the pad printing process include:

- Ink preparation: A thinner is added to the printing ink to adjust its consistency. When exposed to air, the thinner evaporates from the ink’s surface, causing the ink to become tacky and ready for transfer.

- Image pick-up: The silicone pad is pressed into the ink-filled etched plate, and the ink layer adheres to the pad’s surface.

- Image transfer: As the pad is lifted from the plate, the ink layer detaches from the plate and is transported by the pad to the substrate. Thinner evaporates from the ink while on the pad, causing it to become tacky. As the pad presses into the substrate, the ink detaches from the pad and adheres to the substrate’s surface.

- Return to home position: Once the image has been successfully transferred to the substrate, the pad is lifted and returned to the home position.

Pad-Printed Products for Pharmacies

Pharmaceutical manufacturers often face challenges when it comes to adding clear, precise images or prints to curved, sensitive, or uneven surfaces. With pad printing, manufacturers can convey informational or promotional details on a variety of substrates while maintaining product integrity. Common pharmaceutical pad printing products and supplies include:

- Prescription labels

- Liquid medication dispensers

- Medication bags

- Plastic medicine cups

- Pill organizers

- Medicine chests

- First-aid kits

- Promotional and informational magnets

- Custom logo pens and key tags

- Business forms

Benefits & Advantages of Pad Printing

Pad printing provides pharmaceutical manufacturers with several benefits, including:

- Wide substrate compatibility: While most conventional printing methods require a relatively flat and even printing surface, the unique silicone pad used in pad printing can conform to irregularly shaped, recessed, or textured surfaces. Pad printing is also compatible with a variety of materials used in pharmaceutical manufacturing, including silicone, TFE, FEP, and more.

- Superior print quality: Pad printing allows high-resolution images and markings to be transferred to substrates with exceptional precision and consistency. This ensures that all product usage and brand information is clearly visible and legible to the consumer.

- Excellent versatility: Pad printing provides limitless color options and is compatible with a range of UV-curable, biocompatible, medical-grade, and sterilizable inks. This makes it suitable for printing everything from simple barcodes and labels to intricate and colorful company logos that adhere to the industry’s strict quality standards.

- Cost efficiency: Compared with conventional printing methods, pad printing is generally more cost-efficient, easier to set up, and simpler to operate.

Custom Pad Printing from Teca-Print

For over 30 years, Teca-Print has led the pad printing industry with our innovative and sophisticated custom pad printing machines. As a full-service provider and OEM, we have a thorough understanding of the technologies, machinery, and best practices behind the pad printing process. This makes us uniquely qualified to meet the complex and rapidly evolving needs of the pharmaceutical industry when developing industry-compliant, reliable pad printing solutions.

We also work hard to provide quick turnaround times and competitive pricing without sacrificing quality. Our goal is to continually push the limits of pad printing technology to provide crisper, higher-resolution printing options for a range of substrates and applications.

To learn more about our custom pad printer machines for the pharmaceutical industry, please contact us today.