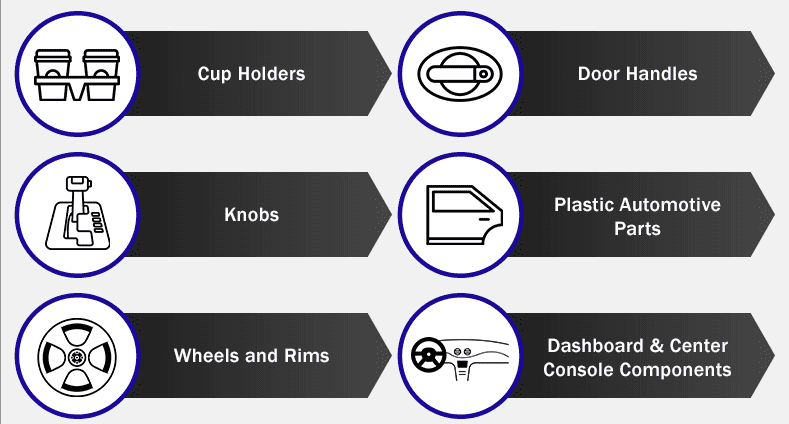

Almost every vehicle component benefits from pad printing technology. The process is beneficial for imprinting parts located under the hood, in the cabin, and on the exterior. These components include a broad range of shapes and substrates that can stand up to performance challenges such as high-temperature exposure.

Pad printing not only offers tailored solutions but is well-suited for products requiring a unique design. It is an ideal way to decorate a variety of surfaces and textures.

The advanced technology allows for the decoration of automotive products using abrasion-resistant graphics and images. The technique is commonly used on vehicle components for indicator markings, safety instructions, notifications, branding, and decorative updates.