Medical device manufacturers depend on an accurate, versatile method for printing onto a wide range of objects and materials. Maintaining maximum print consistency on oddly shaped or textured items presents challenges that are best overcome with pad printing.

In pad printing, technicians achieve high-quality image transfers using a flexible printing pad. Learn more about this versatile process and how it benefits medical device manufacturing.

What Is Pad Printing?

Pad printing is an offset image transfer method for transferring a 2D image onto a 3D part. It’s effective even on irregularly shaped materials and textured surfaces. A pad printing machine requires only three main components to function:

- An etched plate, called a cliché, which contains the desired graphic

- An ink cup, which slides across or “doctors” the etched plate, leaving a thin layer of ink conforming to the exact contours of the etched design

- A printing pad made of a semi-soft silicone material that presses into the plate, transferring the ink to the pad, and then presses the ink onto the intended surface

This ink transfer method may be performed by a range of pad printing machines suited for different image sizes and numbers of colors. Pad printing works on a variety of materials, making it useful for general industrial, automotive, promotional, garment, watchmaking, home appliance, medical device, and other manufacturing sectors.

Pad Printing for Medical Devices

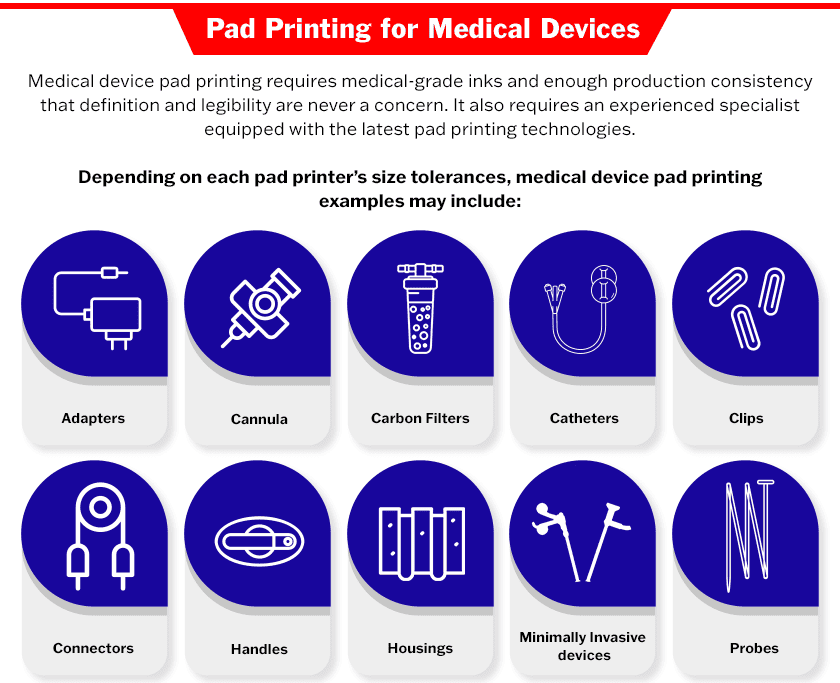

Medical device pad printing requires medical-grade inks and enough production consistency that definition and legibility are never a concern. It also requires an experienced specialist equipped with the latest pad printing technologies. Depending on each pad printer’s size tolerances, medical device pad printing examples may include:

Pad Printing for Medical Devices

- Adapters

- Cannula

- Carbon filters

- Catheters

- Clips

- Connectors

- Handles

- Housings

- Minimally invasive devices

- Probes

- Shafts

- Syringes

- Tubing

- Valves

- Vascular devices

Because pad printing services are usually part of a more comprehensive manufacturing process, they’re subject to many of the same quality controls and tolerance windows. As a result, pad printing providers must be capable of meeting the stringent demands of original equipment manufacturers (OEMs) throughout the entire product development process.

In the medical field, pad printing facilitates high-quality image/text transfer for a range of devices that would otherwise be difficult or impossible to print on. Using pad printing technology, medical device manufacturers can expect the following benefits:

- Compatibility with textured or curved surfaces, irregular shapes, and complex substrates

- Class VI Medical Grade inks

- Enhanced versatility

- Product topography

- Suitable across a variety of industries

- Time-proven processes

Medical Device Pad Printing From Teca-Print

Teca-Print USA develops the most sophisticated pad printing technologies, backed by automated processes and quality controls designed to maintain product consistency even at peak printing efficiency. Our advanced pad printers enable a long list of industries to print their logos and other graphics on objects of almost any size and shape. With over 30 years of experience, we’ve been at the forefront of innovative pad printing technologies, including pad printer research, development, and manufacturing.

To learn more about medical device pad printing or how our services can support your needs, contact Teca-Print USA.