Intro to Pad Printing for Medical Products

Leave a CommentIn the medical industry, labels are imperative for the safety of patients and personnel. Since labeled products are commonly utilized in close or repeated contact with the skin, the ink used to make the labels should be medical-grade (i.e., it is safe for contact with the human body). Otherwise, it can cause adverse reactions, such as skin irritation or rashes.

Medical-grade ink can be applied to part and product labels in a number of ways. However, the preferred method is pad printing.

Why Is Pad Printing the Preferred Labeling Method for Medical Products?

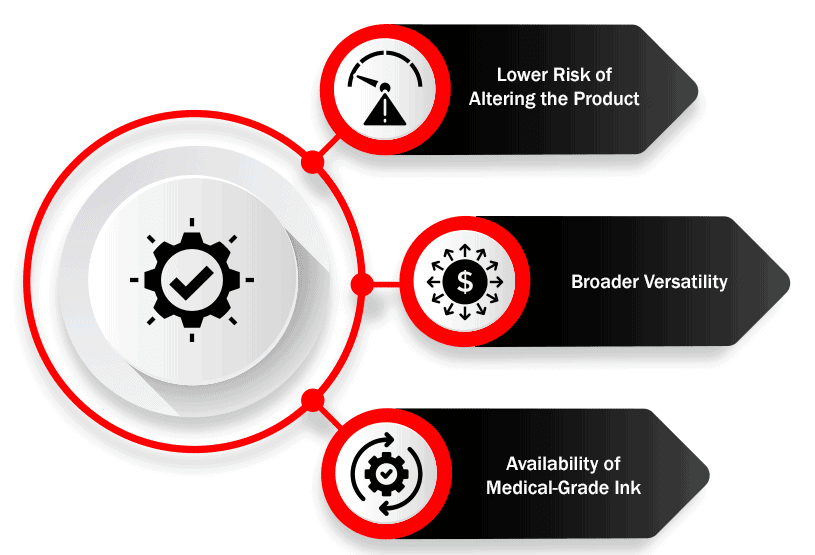

Compared to other printing techniques and technologies, pad printing offers numerous advantages when used to label medical parts and products, including:

Lower Risk of Altering the Product

Some labeling methods can alter the characteristics of a part or product such that it no longer works as intended. For example, applying a heat-activated adhesive label to a medical mask can negatively affect its breathability. Pad printing with medical-grade ink does not modify an object beyond adding a label.

Intro to Pad Printing for

Medical Products Infographic

Broader Versatility

The pad printing method can be used to add labels to a variety of substrates. Additionally, it can be used to label a wide range of parts and products. Manufacturers can easily switch between labeling operations involving different components and materials by changing the ink, pad, and cliche plate.

Availability of Medical-Grade Ink

Some labeling methods do not use materials that are safe for human contact. While not all pad printing ink is medical-grade, there are medical-grade options available.

What Types of Medical Products Are Labeled Using Pad Printing?

Many medical products are labeled using the pad printing method. They can be classified into two main categories: medical devices and personal protective equipment.

Medical Devices

The term “medical devices” encompasses the instruments and machines used for the diagnosis and treatment of patient injuries or illnesses. The types of products that are generally pad printed include:

- Adapters

- Catheters

- Clips

- Syringes

- Tubes

Personal Protective Equipment

In the medical industry, the term “personal protective equipment” refers to medical equipment used to prevent the spread of fluids and other compounds that could cause injury or illness. Two PPE products that are commonly labeled using pad printing are face masks and medical gowns.

The labeling for these products is regulated by the Food and Drug Administration (FDA). For example, medical gowns must be appropriately labeled with the degree of protection they provide (ranging from Level 1 to Level 4). These regulations ensure that users choose the right type and use it correctly. As such, it is important to use a labeling method that offers durability. That’s why face masks and medical gowns are often pad printed since pad printed labels do not easily wear away. Using the pad printing method also ensures the product’s function is not affected and the product’s label does not irritate users.

Medical-Grade Pad Printing Ink From Teca-Print

Pad printing plays a vital role in labeling operations for medical products. When the right ink is used, it forms durable labels that are safe for human contact and are not damaging to the function of the product.

Want to learn more about the pad printing process? Ask the pad printing equipment and supplies experts at Teca-Print! As a premier source of high-quality pad printing machines and consumables, we can answer or address any questions or concerns you may have about the topic. Additionally, if you need ink or other pad printing tools for your medical product labeling operations, we’ve got you covered.