A Specialized Print Technology

Used for a Variety of Industries

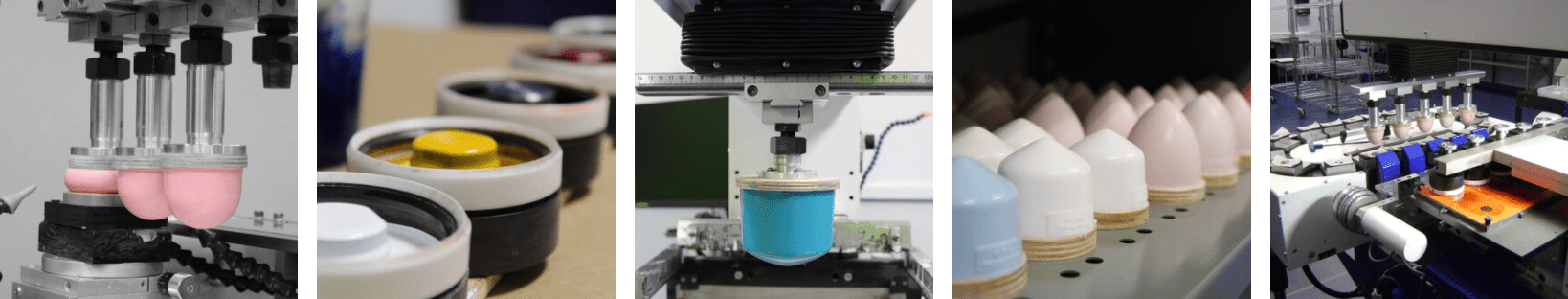

Pad printing is a unique printing process used for transferring 2-D images onto 3-D objects. Like the name, this technology utilizes a silicone ‘pad’ to essentially pick up an image (such as your logo) and transfer it onto a designated object (your product). This technology is typically used to print on difficult or oddly shaped surfaces like a golf ball, toy, syringe or remote. From single-color transfers to a detailed CMYK print process, or even from printing flat objects to oddly shaped ones, pad printing jobs can be complex.

Click here for more common pad printing examples.